Saved from the junk pile. The clock was scheduled to be “parted out”.

Wood weakened by worm holes.

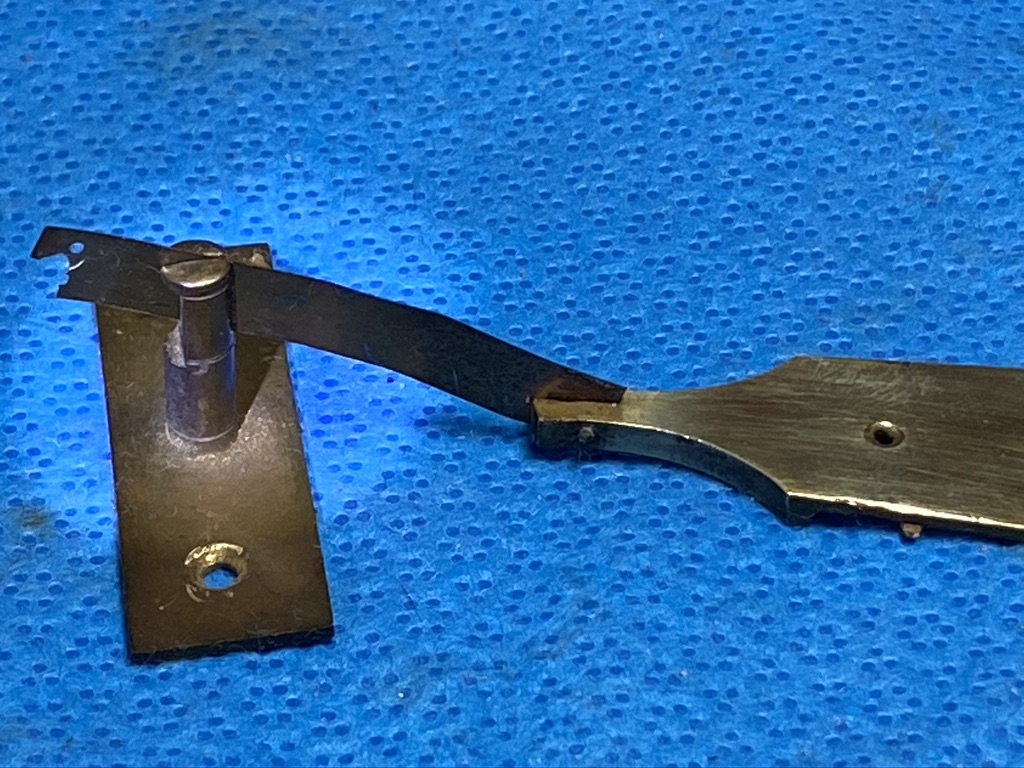

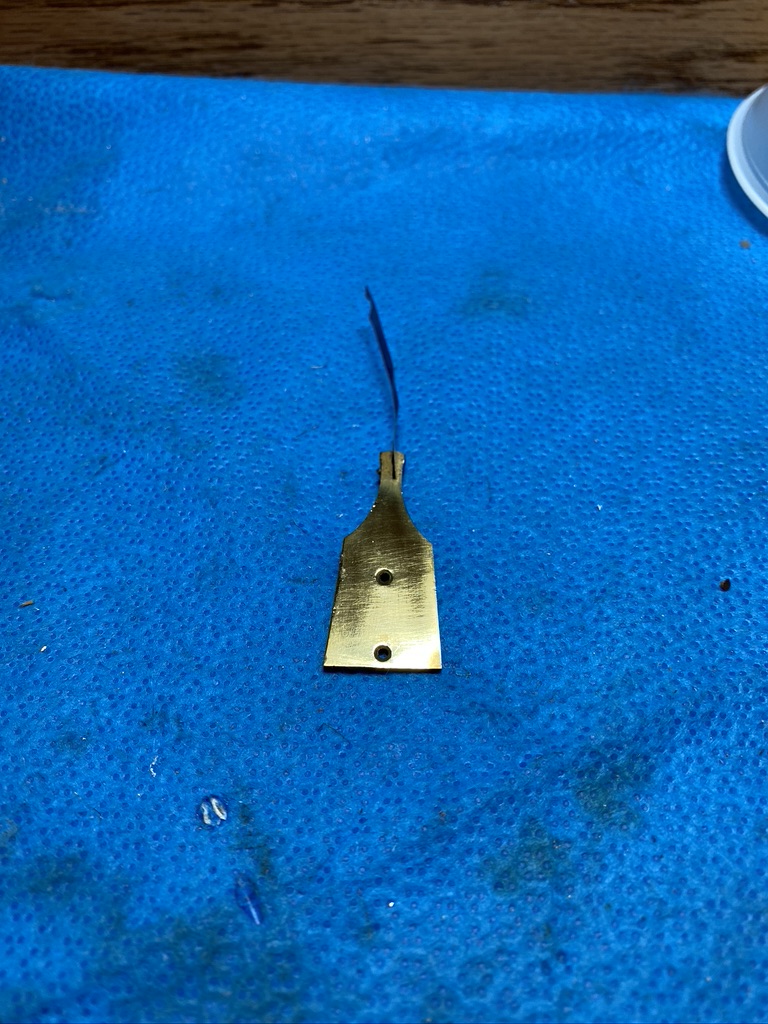

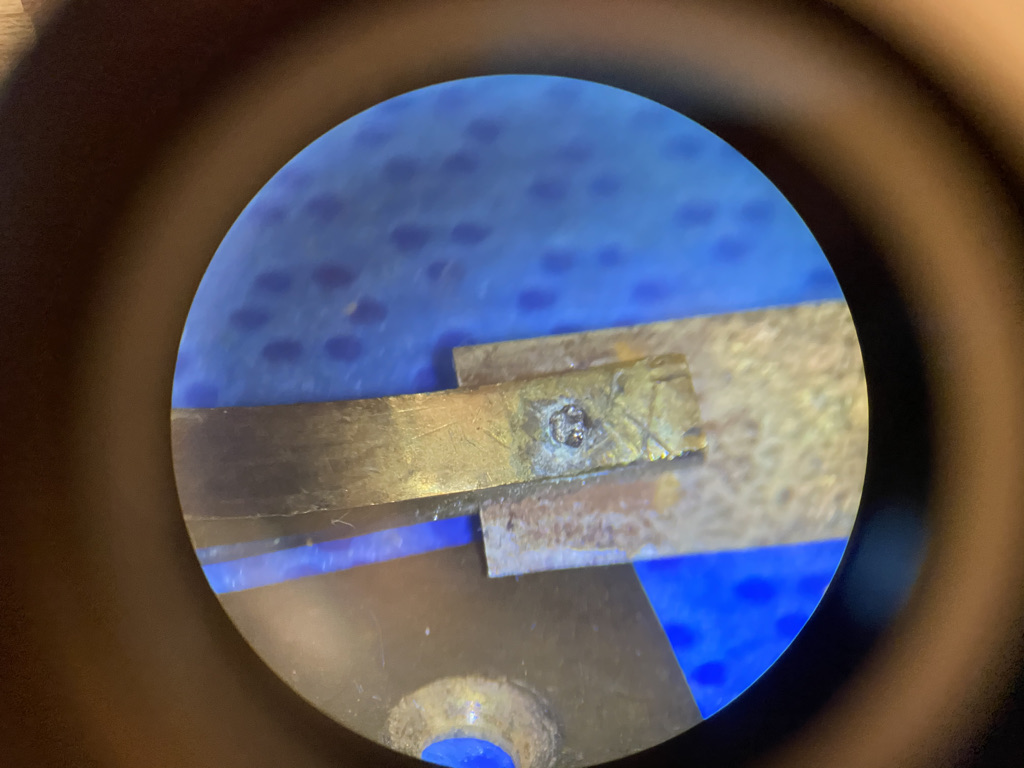

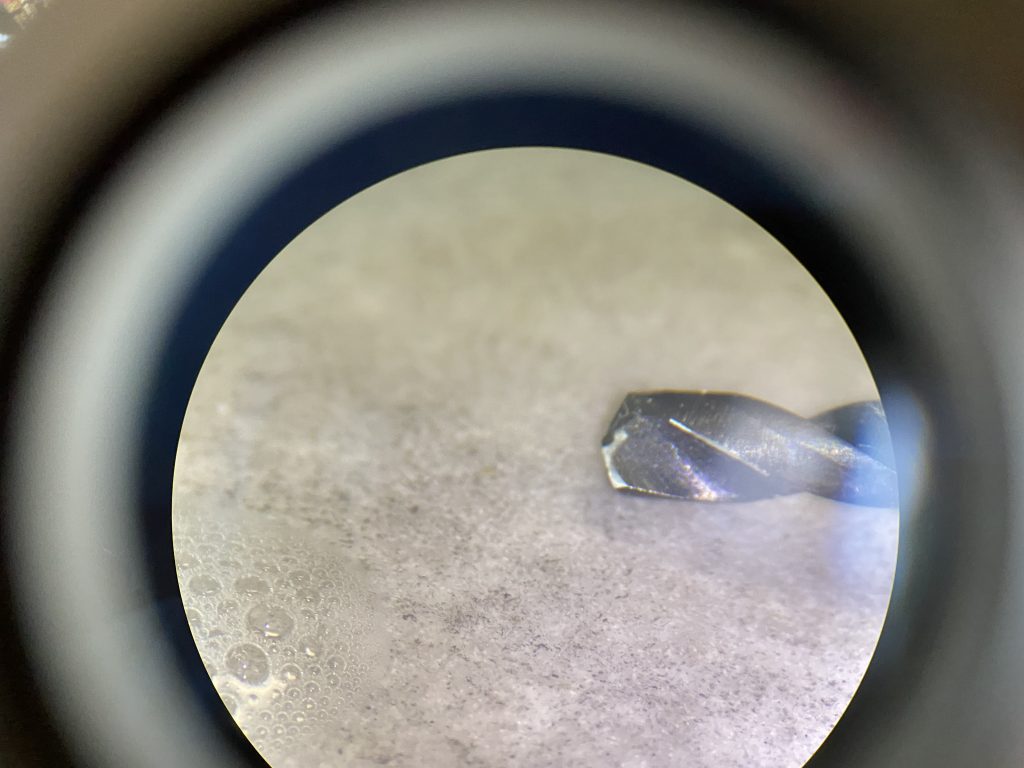

Turns out the base of the hammer tail had broken in half. Rather than making a new base, broken hammer tail base was soldered directly to the strike arbor. Luckily, the arbor was not damaged and I will be able to make a new hammer tail base.

The hands do not appear to be original — a bit short and stubby. Notice that for test purposes, I didn’t attach the hour hand a bit of a mistake as I learned later. (See “Snail Problems” below)

Now to restore the case

The back board and side panes were pretty heavily worm damaged, although the vernier on the back board was in good shape and had a very resilent finish on it. I had planed to refinish it, but since it was in good shape, I decided to leave it “as is”. The base board was too badly damaged to restore.

The Side panes were too far gone to do a partial restoration. Instead I decided to fabricate new panels using the original panels as a pattern. The back plate was in acceptable condition. Finish was surprisingly resilient and only needed cleaning.

The original side panes pieces were a bridle joined by bridle joints. These turned out to be harder to make than I had anticipated. After several tries, I came up with passable joints. The front vertical strut on the original had an oblique hole just below the mechanism mounting to allow a cord attached to the strike release to be accessible from the outside. A tug on the cord released the strike mechanism to repeat the last strike sequence.

Pendulum Restoration

Case Stabilizer Restoration

The case stabilizers had been painted gold and I initially thought they were too far gone to restore. It looked like the screw threads were likely badly rusted and the screws were “frozen” in the attachment block. I ordered replacements from Timesavers, but they seemed to fancy and too bulky for the case. Decided to try cleaning up the old ones with a brass wire brush on the Dremel tool.

Dial Restoration

The dial had a small crack and appeared a bit yellowed.

Weight Restoration

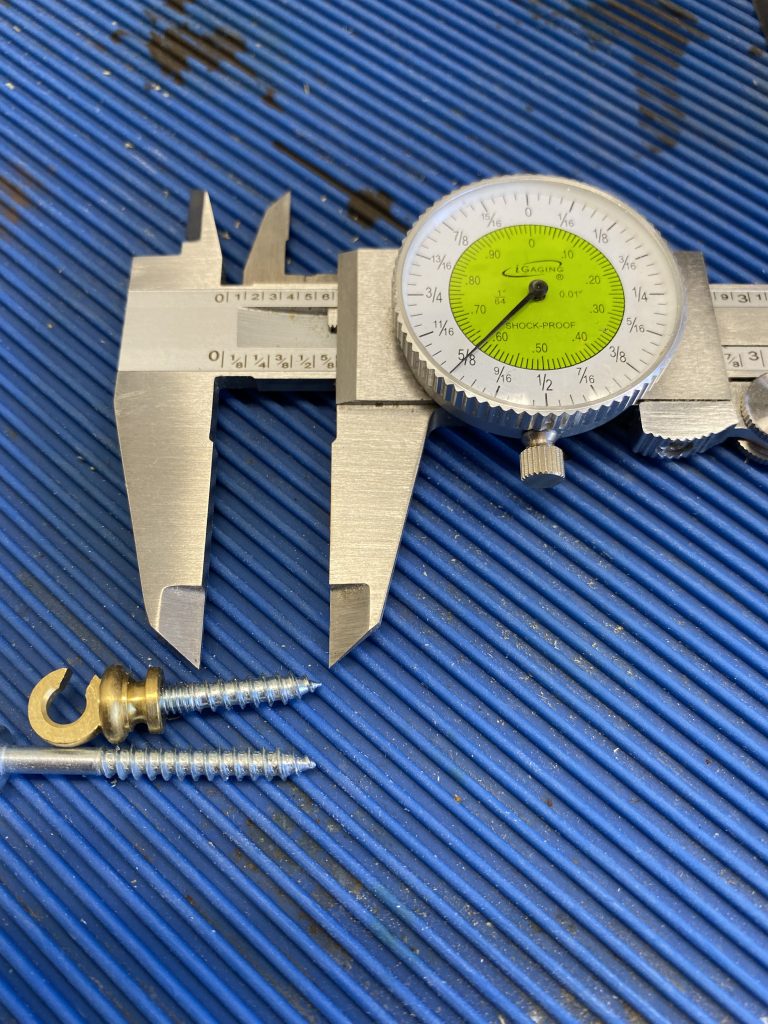

I decided to give the mechanism a run in the case to test my progress. The weights were a bit dented but otherwise seemed OK. One night, one of the weight hooks pulled out and the weight dropped. Luckily, the weight hit the base of the case and did not bounce. No glass damage! On inspection, it was apparent that the hooks while probably original were didn’t have much purchase on the lead. I learned from my fellow clock restorers that replacement hooks were available and would give much better purchase.

Snail Problems

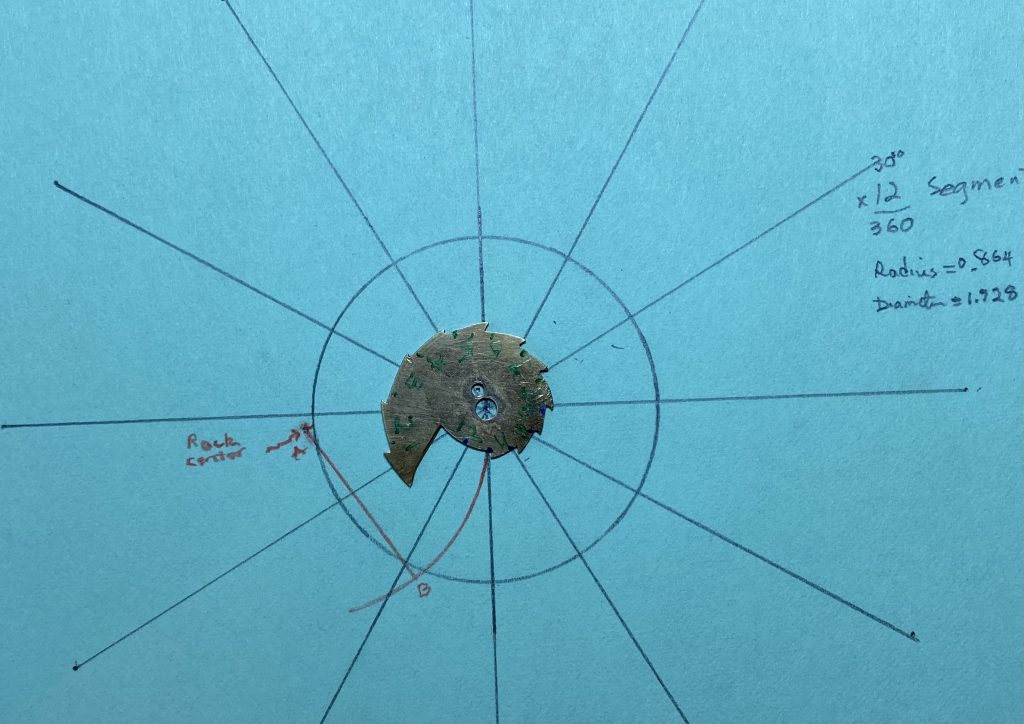

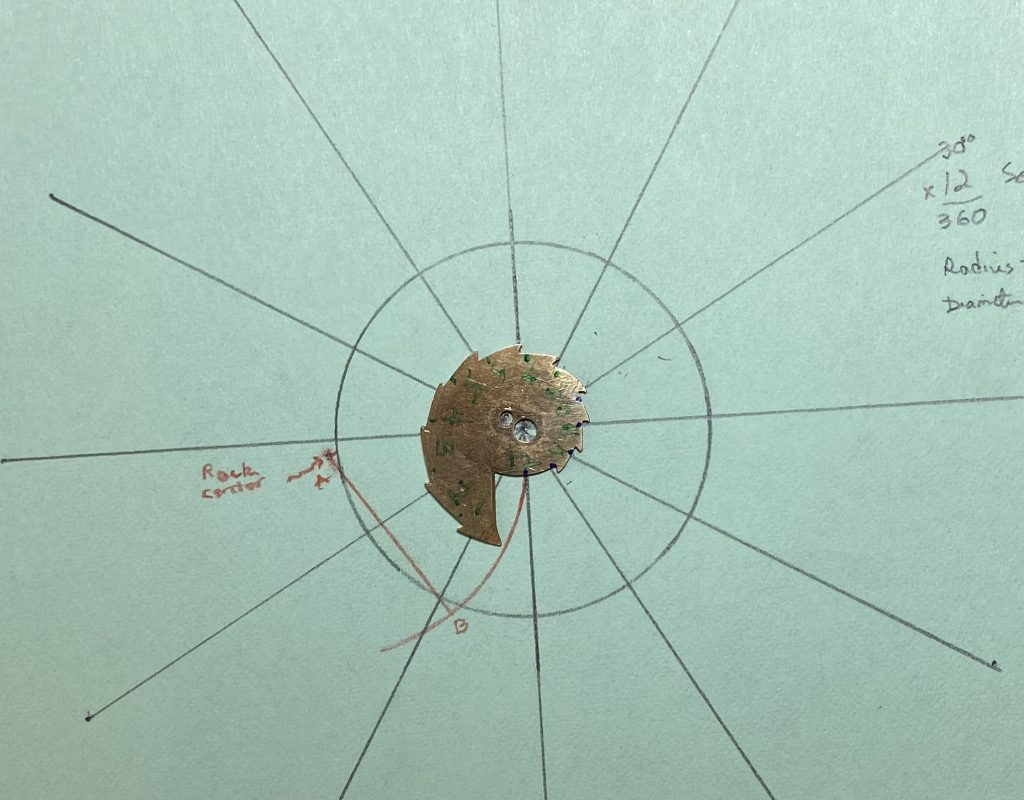

Back to testing with the restored weights, a new problem showed up — the clock would not strike 1:00. It went from 12:00, then 12:00 again, then on to 2:00. Early on when I was running the mechanism in “fast mode” on the test stand, all seemed OK, however, I had only installed the minute hand, so I guess I didn’t actually count the strikes every time. Recall that this clock also strikes once on the half hour (using a mechanism that does not involve the snail). Review of my clock repair books, Don de Carnle and others recommended always checking rack and snail striking in mechanisms by observing the strikes are correct at both the 12:00 and 1:00 positions. I removed the dial and ran studied the action of the rack tail at those times. The problem was the rack tail missing the 1:00 segment on the snail and landing on the 12:00 segment twice — 1:00 segment was too short.

The finished product