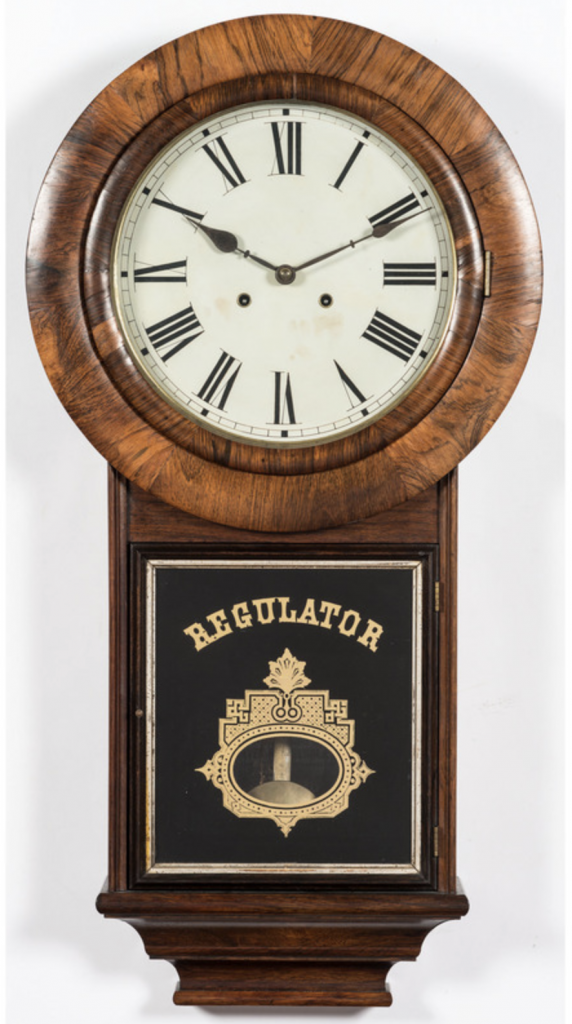

First Impressions

E.N. Welch #3, Eight-Day, Weight Driven Regulator.

A friend of mine inherited this clock some 30+ years ago from his great aunt, Dr. Helen Miller. It is believed to have been the clock in the Meadtown School House, a one room school house built in 1873 near Kinnelon, New Jersey, about thirty miles west of New York City. In 1925 the school was moved to a new two room building. Dr. Miller purchased the school house in 1930. She named it L’Ecole and used it as a country “get away” from her busy OB/Gyn practice in the City. She added rooms, and in 1935 she made her home. She added exam rooms and an office in 1954 and practiced part time out of her home. She passed away in 1990 and left her home to the Kennelon Historical Society. It is now a museum.

The Clock

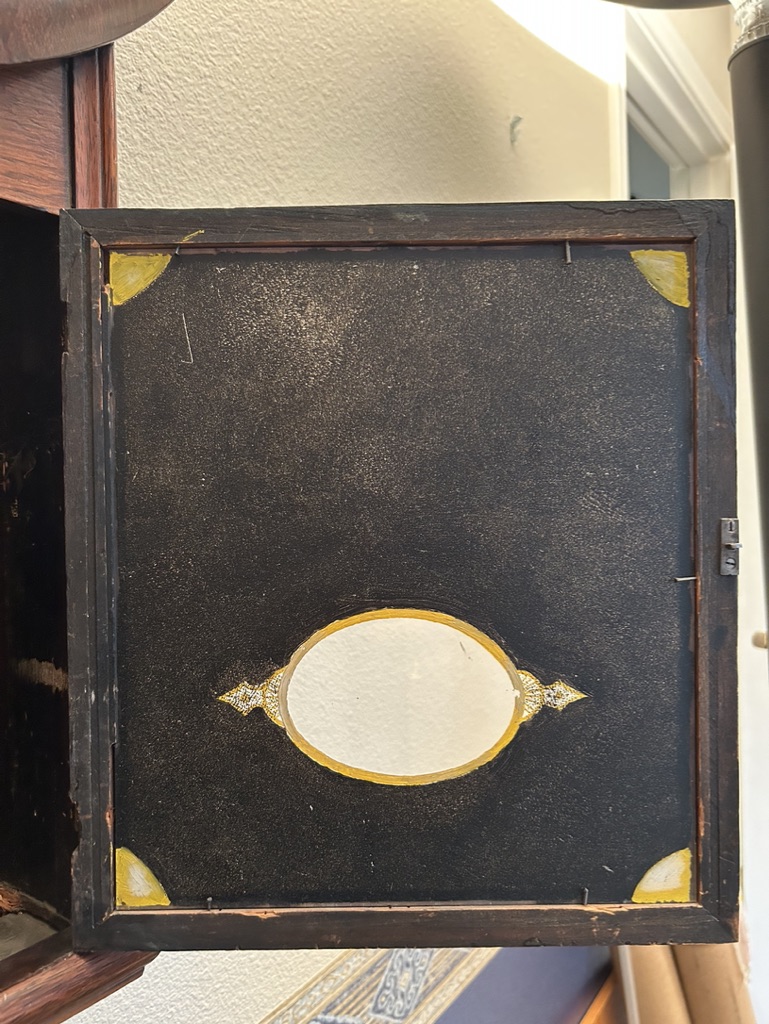

The Welch, Spring and Company made this clock from about 1879 to 1888. The original cost was $16.00. It featured an eight-day, two weight, time only movement. Since each weight had it’s own winding arbor the clock had “maintaining power”, that is, it would continue to run during winding and maintain accuracy over time. The dial is painted on metal and probably original. The case is rosewood veneer with a few loose and a few missing pieces. The upper and lower glass both appear to be replacements. The original lower glass would have had gold leaf around the pendulum bob opening and the word REGULATOR in gold leaf above the opening.

NAWCC Bulletin Supplement #12, “THE WELCH SPRING AND COMPANY”, February 1978

One of several examples of the Welch #3 found on internet auction sites.

The clock was originally made for the S.L. Preston Jewelry Company. I have not found any additional information about S. L. Preston, Jeweler.

Movement Disassembly, Cleaning, & Reassembly

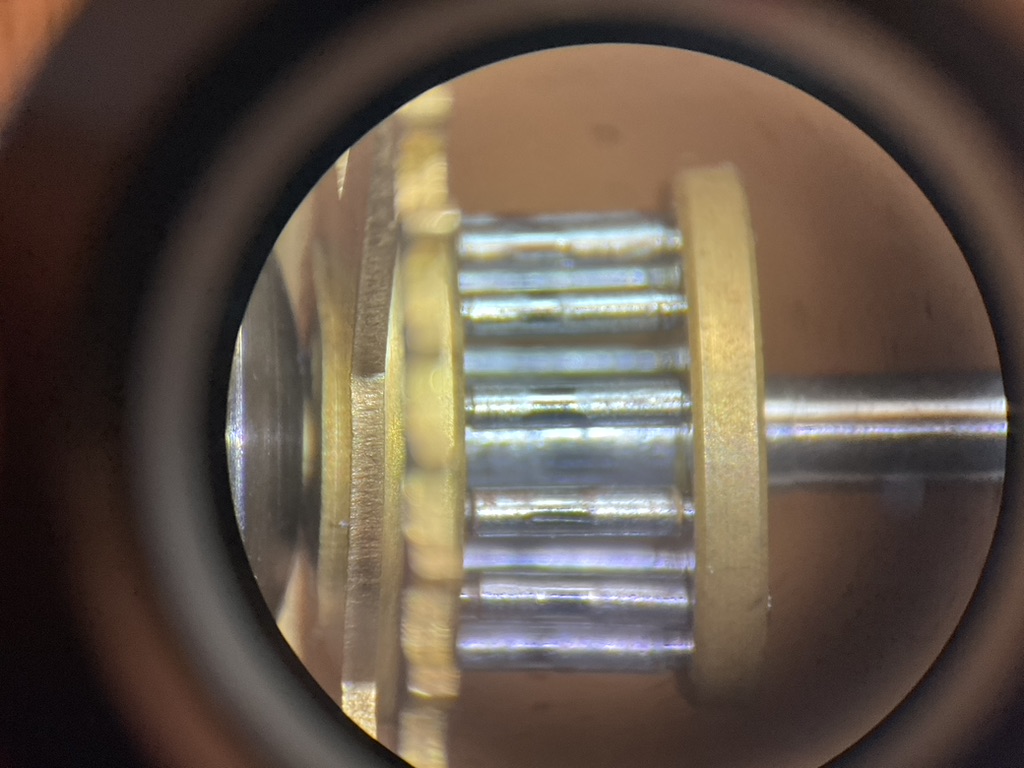

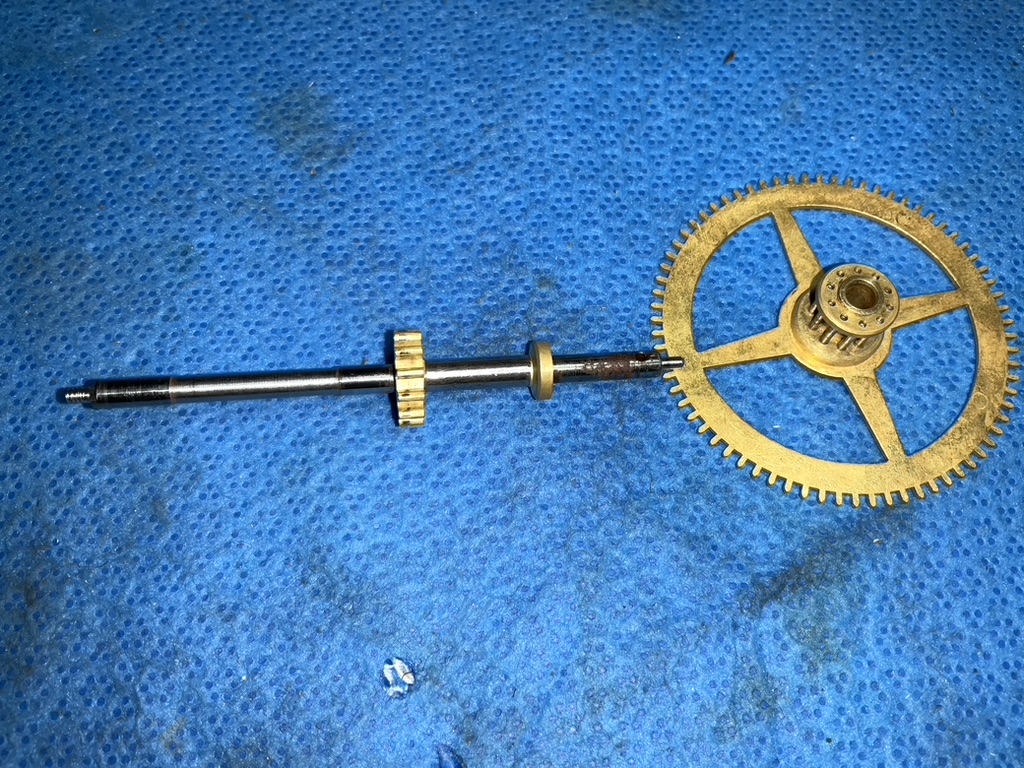

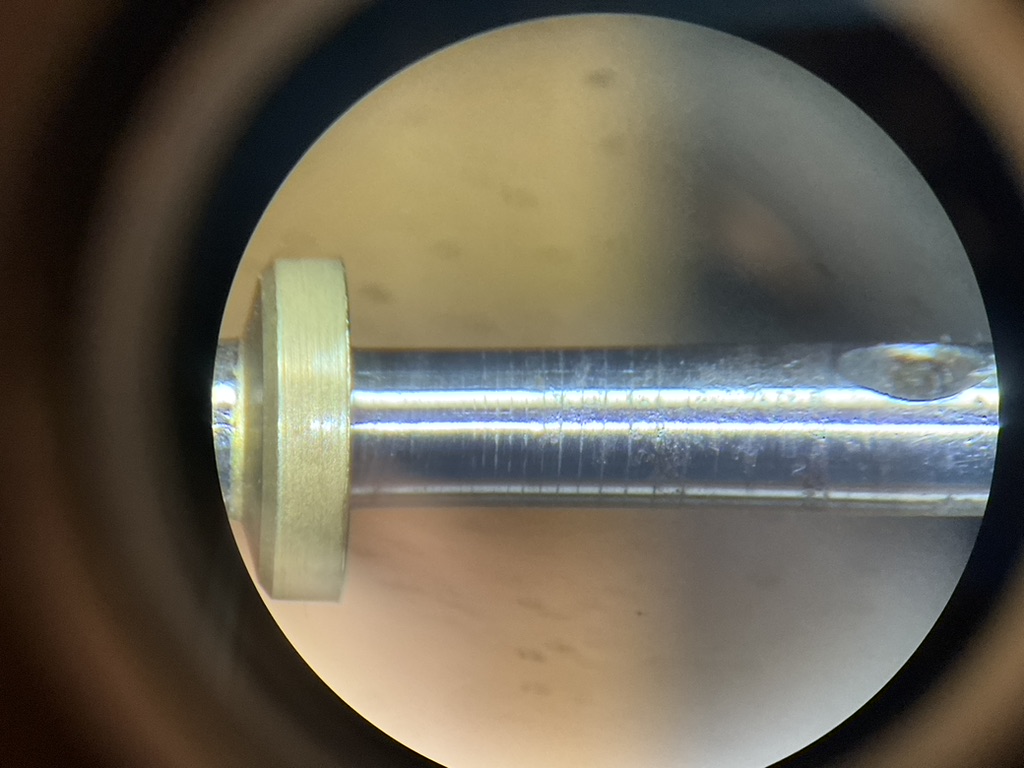

The movement disassembled and cleaned. The weight line was in good condition and did not have to be replaced. The knots were appropriate and could be untied and removed before putting the metal parts in the cleaner, then re-tied. Notably, the lantern pinions have solid roller leaves, or trudles, which are moveable and free to rotate. This meant each trundle had to be individually machined – an added expense. Welch used this design on several models of their clocks as did a few other manufacturers. It was thought at the time that this would reduce wear over time. The idea never caught on as there was no evidence that the concept actually worked. Most of the wheel arbors were in good condition. there was some rust on the back of the center wheel arbor which was removed by stoning. After reassembly, the mechanism ran smoothly.

Case Restoration

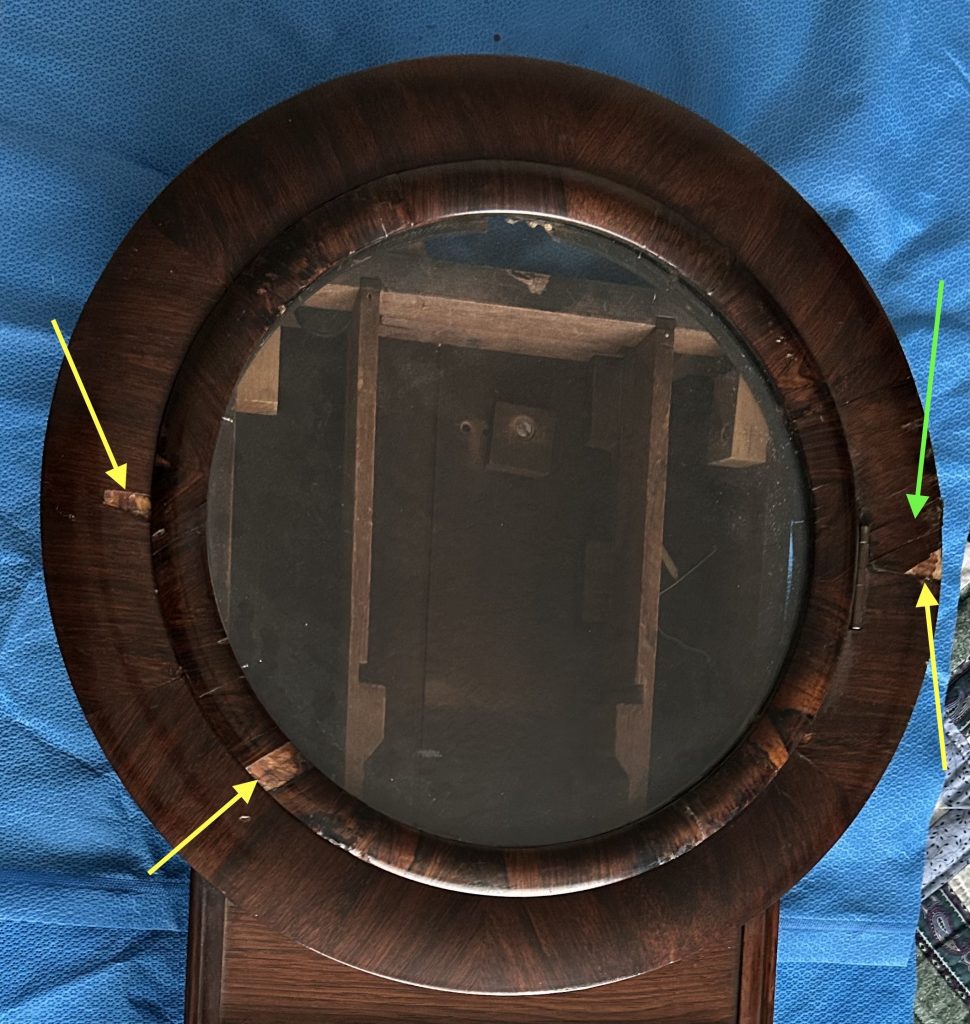

The case is covered with rosewood veneer, but several pieces were loose (green arrow) and a few missing (yellow arrows).

Contours of the rounded case and door frame were first made in cardboard, then cut out of wood (Fig.1) to create a custom clamping form. Contoured wood form was checked against the case curvature(Fig 2). Loose, but still attached, veneer was re-glued (Fig3). Detached veneer was re positioned (Fig 4) . Then new veneer was selected to closely match the grain, fitted in position, glued, and clamped (Fig 5).

Case and door frame ready for finishing after replacing and stabilizing the veneer .

Glass has been replaced as evidenced by the use of simple nails to hold the glass in place and the quality of the reverse glass painting. The over all appearance on the front of the glass actually looks pretty good.

The next step is to French Polish and blend everything in. A thin layer of shellac is rubbed on with a small pad lubricated with a drop of olive oil. Repeated multiple times until a deep luster finish is obtained.

After French polishing – too “shiny” – looks “like new”- not a vintage clock. Brill-Glow is a rotten stone a very fine abrasive which takes off the excessive gleam.

The upper door glass was also held in by small nails. Actually the replacement glass was cut too small in order to accommodate old putty which had not been removed. Putty is usually removed by softening with heat from a small torch or soldering iron, but I had concerns that the thin wood might conduct too much heat and damage or loosen the veneer. Much of the putty on the upper edge of the door had been removed, so I made a small piece of scrap wood, soaked it in water and made it into a curved strip to make a sort of “faux putty” to hold the glass like the original putty, but easier to deal with if needed later. On the lower edge, I removed the hardened putty with a Dremel tool and filled the slot with small strips of curved wood. The wood strips held in place by tiny nails.

Clamps holding the wood strip to make the correct curvature

The restored clock ready to return home.